BambuLab A1 safety risks!

Overheating & potential fire hazard: has anyone else experienced this with their A1 Printer?

Hi everyone,

I’m posting to share a concerning experience with my BambuLab A1, in hopes of understanding if others have encountered a similar issue — and to warn about the potential dangers involved.

What Happened:

- After an overnight print, I noticed the nozzle remained extremely hot. The situation was dangerous, and I was awakened by the smell of burnt electronics and plastic.

- When I subsequently turned on the printer, the nozzle would heat up to 299°C automatically, without any changes to the settings. This forced me to keep the printer off to avoid further damage.

My Interaction with Support:

- I contacted support immediately. Their first response was to apologize for the less-than-ideal experience and suggested that the abnormal temperature might be due to a failure in the hotend. They advised replacing the heating assembly and mentioned that if the problem persisted, the issue could be related to the TH board.

- I asked if the heating assembly was covered under warranty. I was informed that since the printer had been in use for a long time and the hotend assembly (including the heating assembly) is considered a consumable part, it had exceeded the warranty period. Essentially, I was told to replace it at my own expense also if the heating assembly was ruined by a TH board problem.

- I then purchased a new heating assembly — not because it wasn’t functioning (the heater worked so it was intact, and the thermistor detected the temperature so it was intact), but because the excessive heat had “cooked” the plastic and rubber. Based on my observations, I suspected the fault was upstream, likely on the TH board. I hypothesized that there was a dangerous short circuit on the TH board, which could be causing the MOSFET to continuously power the hotend uncontrollably.

- A replacement TH board was eventually sent out by support. However, the support included the heating assembly also, meaning that I ended up with two of them — the one I had purchased and the replacement—without receiving a refund instead.

My Findings:

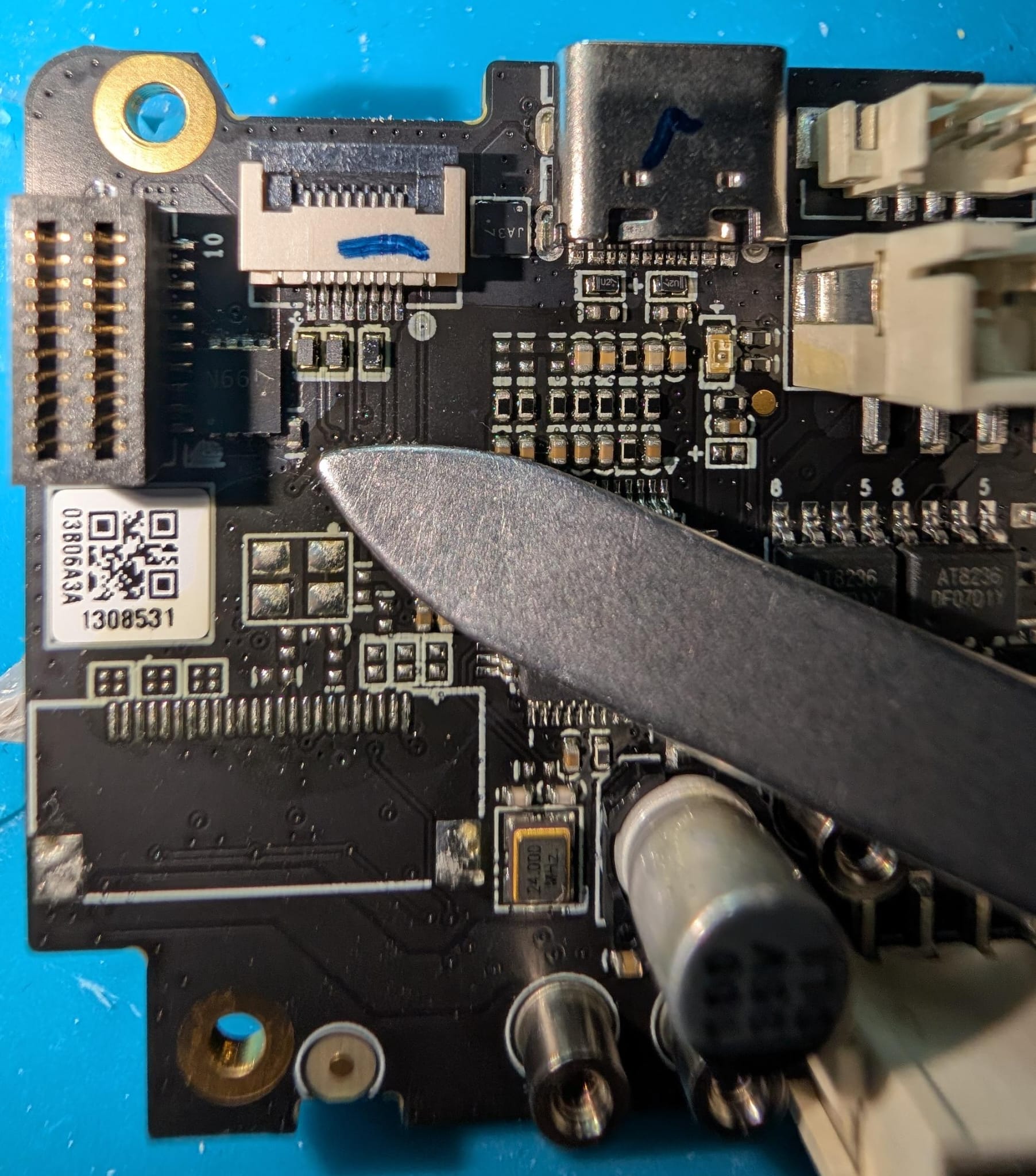

- Thanks to the inspection on the new TH board, I confirmed my suspicions: on the old one I detected a component (likely a diode) in a closed short circuit (he turned in a resistor of approximately 35 ohms), which appears to force the MOSFET (marked N66) into conduction. This results in the hotend being powered continuously, causing temperatures to exceed the range the thermistor can detect (capped at 299°C). No fuses were found on the heater circuit section.

- Although replacing the TH board resolved the immediate issue and returned the printer to normal operation, I remain extremely concerned about its overall safety.

Final Thoughts:

I’m sharing this experience because support’s response significantly downplayed the severity of the problem, despite the real danger of a potential fire hazard. If my findings are accurate, not only was the fault serious, but it also seems that a design oversight might be putting users at risk.

Has anyone else experienced similar issues or noticed any related safety concerns? How have you handled it? Any additional insight would be greatly appreciated.

Stay safe and keep a close eye on your equipment!

Looking forward to your thoughts and experiences.